How can the production and use of glass bathroom bottles reduce the impact on the environment?

The impact of the production and use of glass bathroom bottles on the environment is mainly reflected in resource consumption, energy use, and waste disposal. In order to reduce these impacts, measures can be taken from multiple aspects such as material selection, production process optimization, product design improvement, and consumer behavior guidance. The following are specific solutions and strategies:

1. Use recycled glass materials

(1) Concept

In the production of glass bathroom bottles, recycled glass (also known as broken glass or "cullet") is preferred to reduce the demand for virgin raw materials (such as quartz sand, limestone, and soda ash).

(2) Advantages

Resource conservation: Each ton of recycled glass can save about 1.2 tons of raw materials.

Energy conservation: The temperature required to melt recycled glass is lower than that of melting virgin materials, which can reduce energy consumption by about 30%.

Reducing carbon emissions: The use of recycled glass can significantly reduce greenhouse gas emissions.

(3) Implementation methods

Establish a complete waste glass recycling system and encourage consumers to return waste glass bottles to recycling points.

Increase the proportion of recycled glass in the production process (the current industry standard is usually 30%-50%, which can be further increased to more than 70%).

2. Lightweight design

(1) Concept

Through optimized design, reduce the wall thickness or weight of the glass bottle while maintaining its strength and functionality.

(2) Advantages

Resource conservation: Reduce the amount of glass material used and reduce the demand for raw materials.

Transport efficiency: Lightweight design reduces the weight of the bottle, thereby reducing fuel consumption and carbon emissions during transportation.

Cost reduction: Reduced material usage directly reduces production costs.

(3) Implementation method

Adopt advanced mold design and molding technology (such as blowing process optimization) to achieve lightweighting.

Test the impact resistance and heat resistance of the bottle to ensure that lightweighting does not affect performance.

3. Environmentally friendly production process

(1) Concept

Improve the process flow of glass production and adopt more environmentally friendly technologies and equipment.

(2) Advantages

Energy saving and consumption reduction: New kilns and heating technologies can significantly reduce energy consumption.

Pollution control: Install exhaust gas treatment equipment to reduce the emission of pollutants such as sulfur dioxide and nitrogen oxides.

Recycling: Introduce a closed-loop water circulation system to reduce water waste.

(3) Implementation methods

Replace traditional fossil fuel kilns with electric heating kilns to reduce carbon emissions.

Install tail gas purification devices to capture harmful substances and treat them harmlessly.

Promote the use of clean energy (such as solar energy and wind energy) for glass production.

4. Encourage reuse

(1) Concept

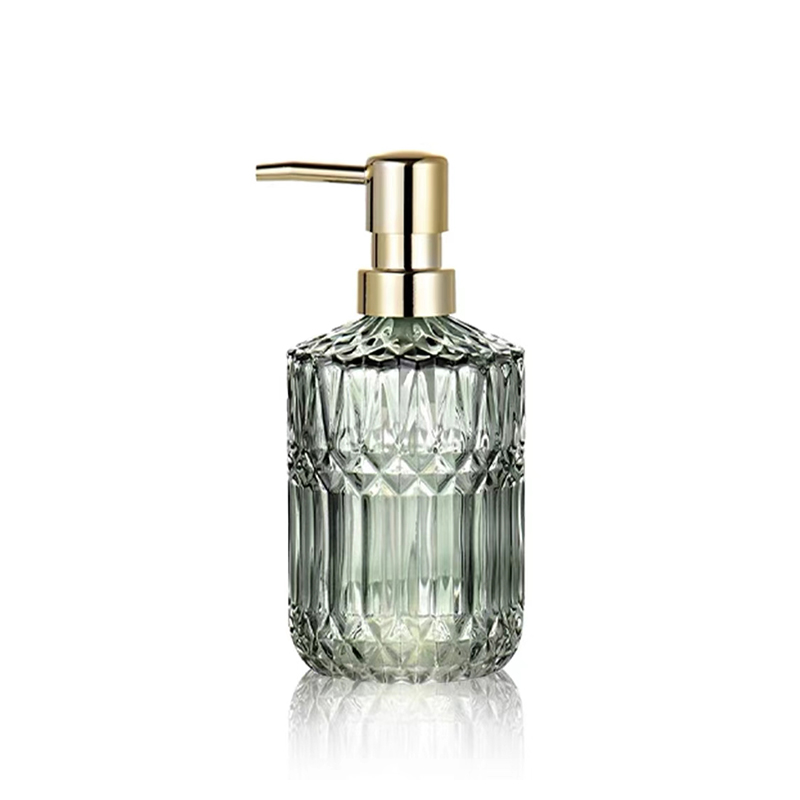

Encourage consumers to reuse and reduce the consumption of disposable products by designing durable and easy-to-clean glass bathroom bottles.

(2) Advantages

Reduce waste: Reuse can significantly reduce the number of discarded glass bottles.

Extend product life: High-quality design enables bottles to be used for a long time and reduces the frequency of replacement.

Enhance brand image: Environmental protection concepts are in line with the preferences of modern consumers and help enhance brand value.

(3) Implementation methods

Design wide-mouth bottles or detachable structures to facilitate user cleaning and refilling.

Provide refill pouches or bulk liquid filling stations to reduce the need to buy new bottles.

Mark environmental protection tips on the packaging to encourage consumers to reuse.

5. Sustainable packaging and transportation

(1) Concept

Optimize the packaging and transportation methods of glass bathroom bottles to reduce resource consumption and environmental impact.

(2) Advantages

Reduce packaging waste: Use recyclable or degradable packaging materials (such as cardboard, bioplastics).

Reduce transportation costs: Reduce carbon emissions during transportation through compact packaging design and efficient logistics planning.

(3) Implementation method

Use recyclable cardboard instead of plastic foam as cushioning material.

Use stacking packaging design during transportation to maximize space utilization.

Select low-carbon logistics partners to promote green transportation.

This comprehensive environmental protection measure not only helps to protect natural resources, but also reduces the company's operating costs, enhances brand image, and meets consumers' growing environmental protection needs.

English

English Español

Español